About Us

Wuhan Optics Valley Quantum Technology Co., Ltd. a subsidiary of Vital Technology Co., Ltd., is a high-tech enterprise specializing in high-end laser and detector chips, integrating R&D, manufacturing, and sales. Its business covers laser detection, high-speed optical communication, quantum secure communication, and other fields. The company possesses 35 independent intellectual property patents. Its expert team includes recipients of the European Academy of Sciences Lifetime Achievement Medal, appointees to national and provincial key talent programs, as well as honorees of Wuhan’s “Huanghe Talents” Plan and the East Lake High-Tech Development Zone’s “3551” Talent Plan.The company operates an advanced optical chip production line and packaging platform in Wuhan, with a 3,000-square-meter Class 1000/100/10 cleanroom equipped with over 100 sets of advanced production and testing equipment. In addition, a new 7,000-square-meter facility is currently under construction. The company has established a complete R&D, production, and quality management system, and has obtained multiple patents. Its core technical team possesses extensive experience in compound semiconductor technology development. Based on mature chip process platforms using silicon, InP, and GaAs material systems, the company has successfully developed a number of products. It is committed to innovating high-end chips and providing downstream customers with high-quality, full-range optoelectronic chip products and technical services.

Production Platform

Philosophy

- Our platform introduces internationally advanced design concepts and incorporates integrated circuit production line experience, establishing a pioneering III-V optoelectronics R&D and production platform in China.

Features

- The core area incorporates a standalone, embedded vibration-resistant platform reinforced with special materials—the first of its kind in China. This innovative structure offers extreme difficulty in construction and achieves an exceptional VC-E level micro-vibration resistance.

- The platform leads the domestic III-V semiconductor industry in contamination control and operational management. The core cleanroom area includes vertically ventilated Class 10, 100, and 1000 environments, and horizontally ventilated Class 1000/10,000 spaces, totaling nearly 2,100 m².

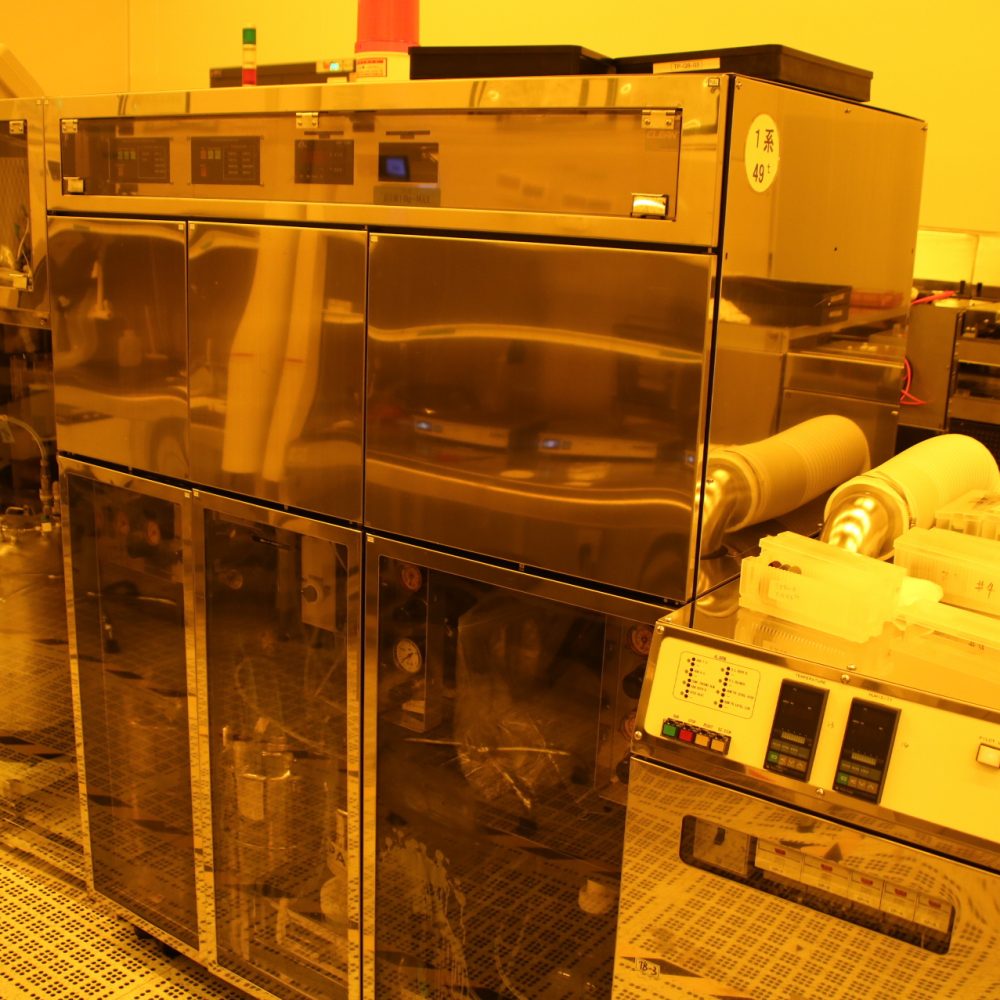

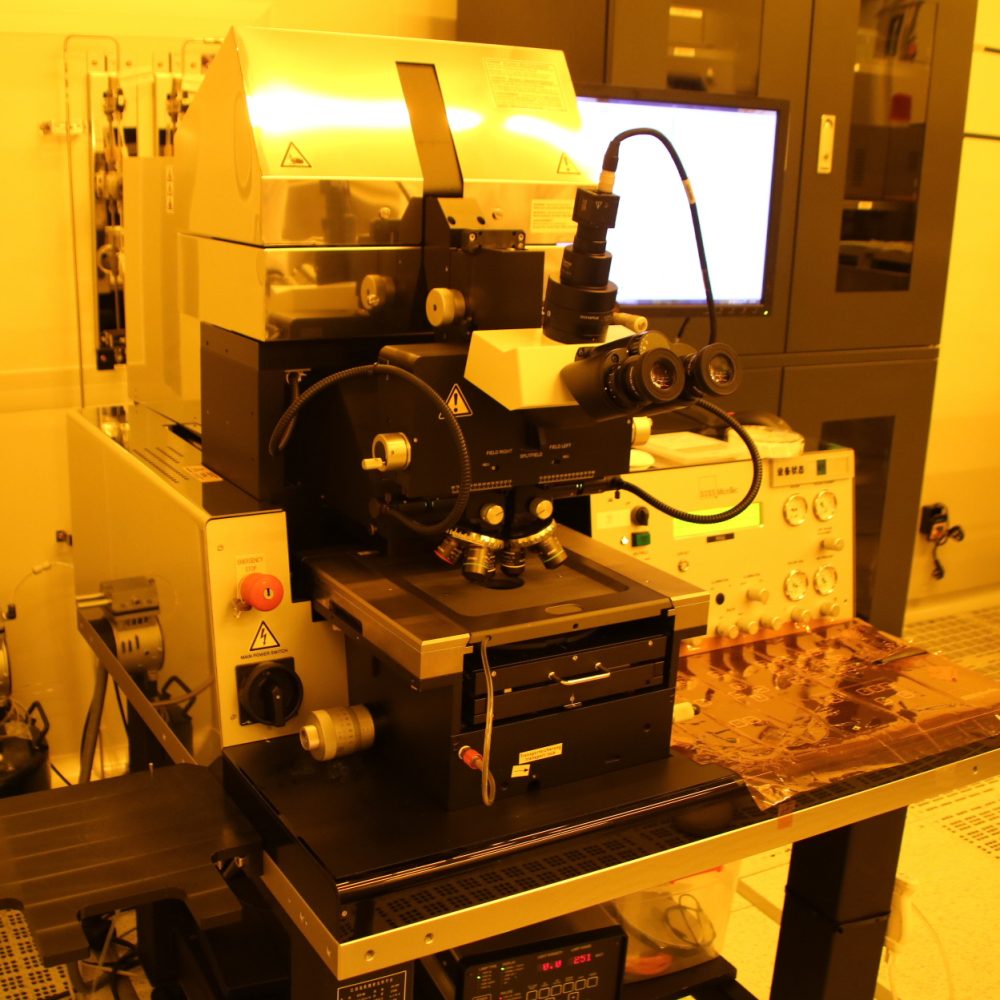

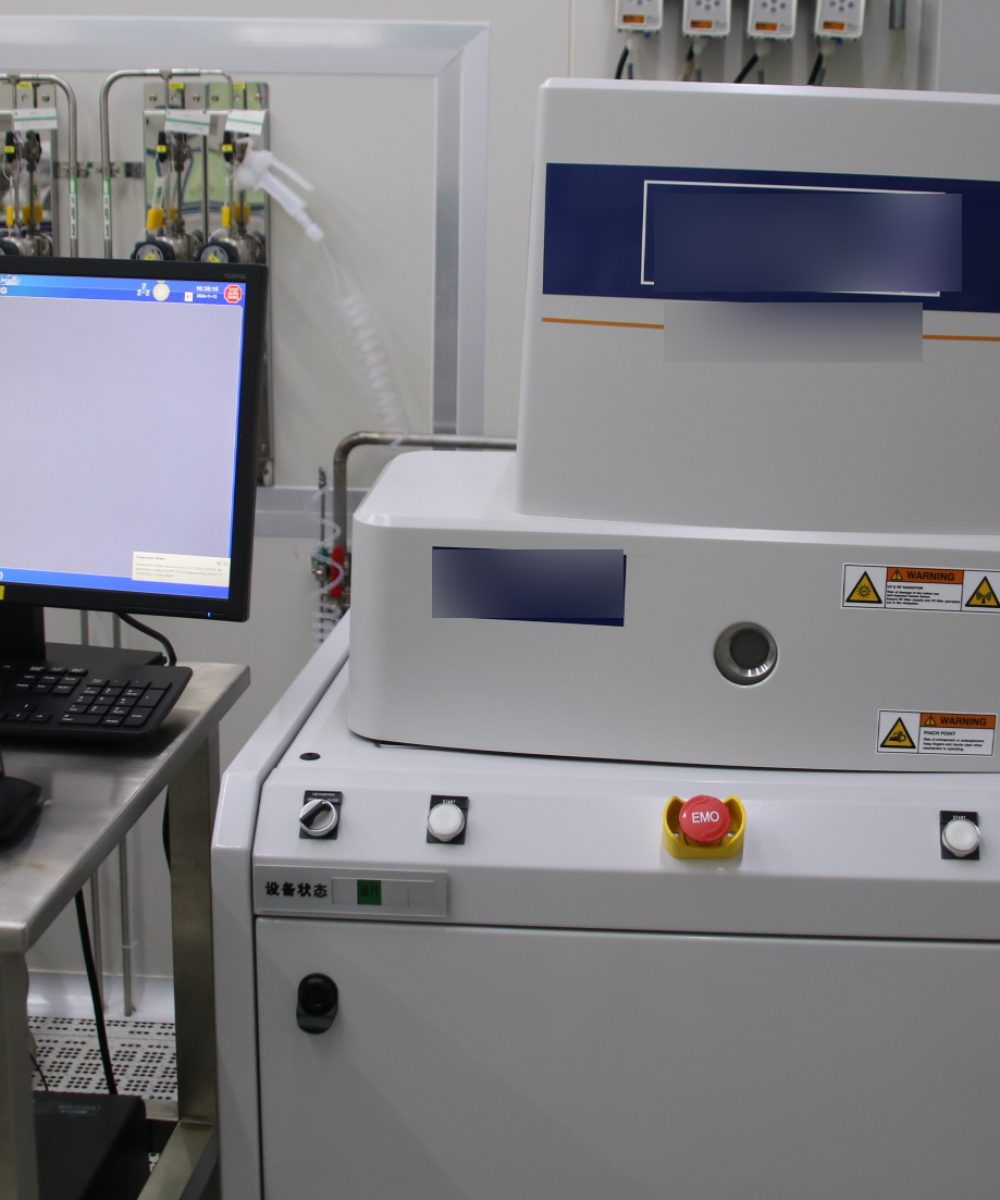

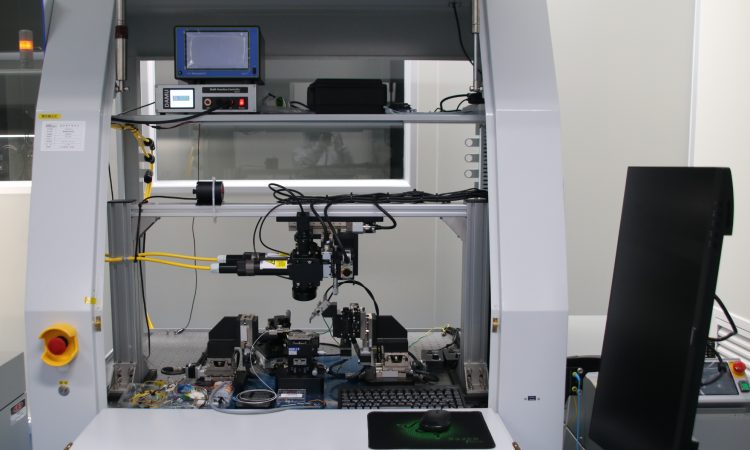

Equipment & Capacity

- Equipped with integrated circuit production tools including MOCVD, stepper lithography systems, fully automatic coating and developing machines, and automated optical inspection (AOI).

- Over 100 sets of key process equipment support epitaxial characterization, precision diffusion, chip manufacturing, and testing.

- Annual production capacity reaches tens of millions of chips.